| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | HEYA |

| Model Number : | HY-212 |

| Certification : | ISO9001 |

| Price : | Negotiable |

| Payment Terms : | T/T,D/A,D/P,Western Union |

| Supply Ability : | 800 pcs/week |

| Delivery Time : | 15-20 work days |

(高精度电铸工艺 家电工具手柄模具 防滑纹理部件)

Suitable For Home Appliance Handles (Rice Cooker, Blender, Vacuum Cleaner) & Tool Handles (Wrench, Screwdriver, Pliers) | ±1μm Anti-Slip Texture Precision | Works With Food-Grade & Wear-Resistant Resins (PP, ABS, TPR, PC) | Supports Custom Grip Patterns (Ribbed, Knurled, Grainy)

| Attribute | Value |

|---|---|

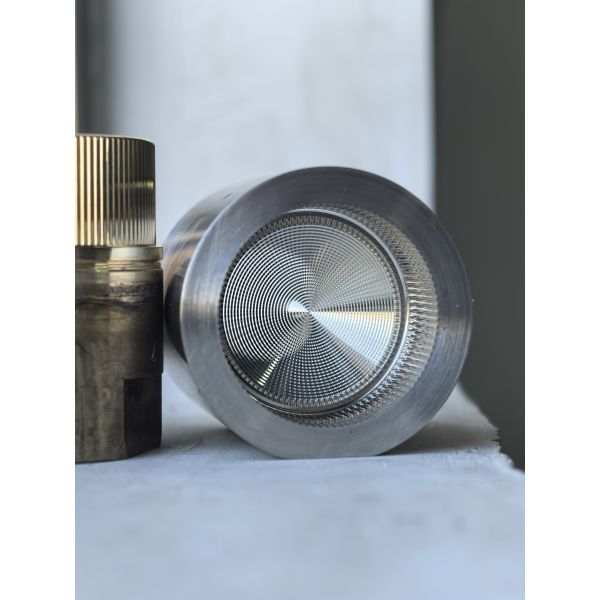

| Product Name | High Precision Electroformed Handle Molds – Anti-Slip Texture For Home Appliances & Tools |

| Highlight | Electroformed anti-slip textures, food-grade safety, high wear resistance, customizable grip patterns |

| Tolerance | ±0.002mm (mold cavity dimensions); ±1μm (texture depth/line spacing); ±0.5° (texture angle) |

| Hardness | 50-55 HRC (nickel-cobalt alloy, 18-22% Co); 45-50 HRC (high-purity nickel, 99.95%) |

| Feature | Ra 1.5-6μm adjustable anti-slip roughness, food-grade nickel alloy (FDA-compliant), corrosion-resistant (oil/water/cleaners), 99.9% texture replication fidelity |

| Processing Method | High-precision electroforming (nickel ion deposition) + Laser texturing (anti-slip pattern engraving) + Post-processing (edge smoothing) |

| Material | Nickel-cobalt alloy (high wear resistance for tool handles), high-purity nickel (food contact safety for appliance handles), nickel-chromium alloy (corrosion resistance) |

| Application | Home appliance handles (rice cooker lids, blender grips, vacuum cleaner handles) & hand tool handles (wrenches, screwdrivers, gardening pliers) |

Engineered exclusively for home appliance and tool handle production, this high-precision electroformed mold combines the strengths of electroforming (for ultra-accurate texture replication) and anti-slip pattern design—solving the core pain points of "poor grip" and "short service life" in handle products. Unlike traditional machining molds (which struggle with consistent texture transfer), electroforming deposits nickel alloy layer by layer to replicate ribbed, knurled, or grainy anti-slip patterns with ±1μm precision—ensuring every handle has a uniform, tactile grip that prevents slipping even with oily or wet hands.

Built with food-grade and industrial-grade nickel alloys, the mold meets FDA standards for appliance handles (safe for direct food contact) and industrial durability requirements for tool handles (resistant to repeated torque and abrasion). It supports high-volume production (300,000+ cycles) without texture degradation, making it ideal for both consumer electronics brands and tool manufacturers seeking reliable, cost-effective handle molding solutions.

| Category | Target Products | Texture Recommendation |

|---|---|---|

| Home Appliances | Rice cooker lids, blender grips, vacuum cleaner handles, air fryer knobs | Ra 1.5-2.5μm ribbed/grainy texture (comfortable, easy to clean) |

| Hand Tools | Screwdrivers, wrenches, pliers, gardening shears | Ra 4-6μm knurled/deep grainy texture (high grip for torque) |

| Power Tools | Drill handles, sander grips, circular saw handles | Ra 3-5μm cross-hatched texture (shock-absorbent, anti-slip) |

Whether you’re producing kitchen appliance handles that need safe, comfortable grip or industrial tool handles that require durable, high-torque grip, our high-precision electroformed molds deliver the anti-slip performance, safety, and consistency your products demand. Backed by ±1μm texture precision and 300,000+ cycle durability, they help you create handles that stand out in quality and user experience.

|